JewelsPrint is an innovative software package that helps jewelry manufacturers to efficiently create wax casting trees. This software can overcome the limitations of traditional manual methods through its advanced algorithms and automation. It results in significant improvement in speed, precision, cost-effectiveness, and design. It will then provide a basis for higher performance, innovation, and ultimately success in the contest of the jewelry manufacturing industry.

The Limitations of Traditional Wax Tree Casting

While the traditional methods of wax tree casting are deeply rooted in history and artistry, they often come with inherent limitations:

- Time-consuming: The man-made process of creating branched casting wax trees is time-consuming and produces a limited number of master casts each time

- Prone to human error: Human errors unavoidable in manual operations lead to flawed products and repeated scraps at the end of such processes.

- Material-intensive: The traditional way usually spends the amount in excess which increases the costs and environmental effect too.

- Labor-intensive: Artisans may take too much time to perform routine tasks, which makes it impossible to get in full swing and achieve the full rate of productivity.

Introducing JewelsPrint: Automated Wax Casting Tree Generation

JewelsPrint is an innovative software tool that uses a smart-based solution to automate the nature of wax tree jewelry creation. JewelsPrint can meet the challenge of making wax casting trees that have super speed, high precision, and low cost grating the intelligence of algorithms. This will reshape the process of manufacture of jewelry.

Key Features and Benefits:

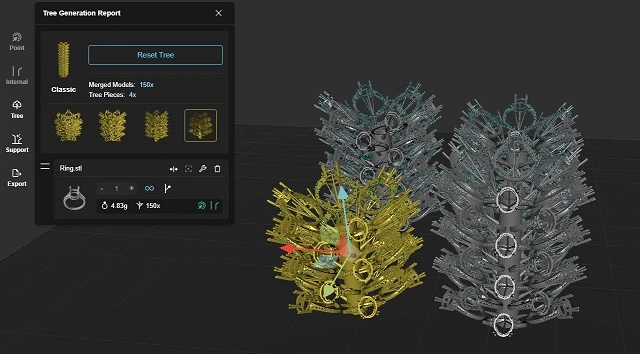

- Automated Casting Tree Generation: JewelsPrint’s key functionality is the algorithms that generate a casting tree dynamically for any jewelry design based on the size and composition of your design. This automatic process greatly speeds up production and labor requirements, enabling you to bring down your whole process of work to an absolute minimum.

- Jewelry Model Diagnosis & Repair: Before the tree is generated by JewelsPrint’s algorithms, they perform a thorough analysis as well as diagnosis of your 3D jewelry models, this process helps identify and fix any possible defects or errors. This auto-repairing functionality guarantees perfect results and is devoid of any manual interventions.

- Optimized for All 3D Printing Technologies: Using resin, FDM, powder-based, or any other method of 3D printing with JewelsPrint is effortless matching your existing settings. The software that we have developed prepares the casting trees along with the optimized support structures that are suitable for your printer. The automatic algorithms are meant to dissect your component drawings and meticulously position those supports, anchoring, and material utilization to have a predefined fit that is closer to perfect. The resulting strategy being both comprehensive and fragmented prevents issues such as deformities, excessive materials wastage, and some particularly post-processing requirements. As I have worked with the use of additive manufacturing you can see the consistency of the printing result with no flaws which are covered to accelerate your production regardless of the level of printing. Our innovation cuts the time to make a new decision or to adapt an existing one.

- Material Usage Prediction: JewelsPrint achieves this by intelligently calculating the amount of material required for each wax casting tree, this way enabling you to reduce wastage and properly manage your resources. With this predictive ability of production planning, not only it is cost-efficient but also improves your overall operative performance and efficiency.

- Purpose-Built for Innovative Jewelry Manufacturing: JewelsPrint, developed to cater to the jewelry industry alone, surpasses the low-practical-caliber manual wax tree production methods. Through its sophisticated algorithms and special features, jewelers are released from the inhibitions to express themselves fully creatively with designs that were previously out of reach. This way, mankind could not only launch innovation in jewelry manufacturing but also achieve perfection in its outcomes.

- Lower Expenses: JewelsPrint automates its procedures, minimizes material waste, and simplifies its workflows thus helping you in reducing your production expenditures. By cutting down on the charge of labor, material waste, and the duration of production, JewelsPrint gives you an affordable and effective solution, that will influence and enhance your business.

How JewelsPrint Works

Utilizing JewelsPrint is a straightforward process that seamlessly integrates with your jewelry 3D printer:

- Import your model file in the.STL format.

- Assign connection points for each jewelry model and select the desired tree layout.

- JewelsPrint automatically generates an optimized jewelry casting tree, complete with necessary smart supports, ready for resin 3D printing.

By adopting JewelsPrint, you will go through a great transition in how you design and make your wax-casting tree pattern; embracing modern technology and opening your gate to new realms of precision, cost-effectiveness, and efficiency. Empower your crew, hit the target, and rewrite the new standards of your art with JewelsPrint.

Comparison with Traditional Methods of Wax Tree Making

On the one hand, the ancient wax tree-making technique has been highly appreciated as a fine art and a cultural heritage whereas, on the other hand, it might not meet the modern requirements of mass jewelry production. JewelsPrint stands out as a different approach by resolving the existing drawbacks of traditional ways but maintaining the value of the lost wax casting method.

Design Limitations:

Traditional methods: While manual wax tree model construction does provide certain design benefits, it also severely limits the complexity of details and sometimes prevents the creation of modern jewelry pieces.

JewelsPrint: JewelsPrint, by surpassing the limitations of manual tasks, opens new creative possibilities and gives jewelers to design and create even the most daring and complicated architectural designs.

Time-Efficiency:

Traditional methods: The process of meticulously shaping multiple wax trees by hand is quite a labor-intensive and long-haul endeavor, therefore the low production volumes.

JewelsPrint: The tree generator furnished by computer machines reduces 90% of the time a production which renders a high rate of turnaround as well as large output.

Precision and Consistency:

Traditional methods: Getting done with the manual processes have been associated with human error, and thus inconsistency, errors, and reworks are probable to follow.

JewelsPrint: The Use of advanced algorithms allows to design of trees that are accurate and uniform thus eliminating the possibility of having numerical errors and minimizing the rework.

Material Optimization:

Traditional methods: Unnecessary use of wax and material waste is usually found, thus contributing to the rise in operating costs and environmental impact.

JewelsPrint: The use of antimicrobial material prediction and in wax-consumption saving designs by up to 50%, leads to cutting down expenses and minimizing waste.

Labor Utilization:

Traditional methods: There are a lot of artisans who need help to either add their creative abilities or produce because they are busy dealing with repetitive jobs.

JewelsPrint: Artists are free to specialize in the design and attach details because, on probable computers, automation of Non-creative tasks can be done, enhancing creative abilities and output.

Scalability:

Traditional methods: The lack of automation for several processes is the broadest challenge, which also prevents the business from growing with pace.

JewelsPrint: The automation of workflows and process efficiency enables businesses to scale up corporate operations in a smooth and controlled fashion, ensuring the meeting of the rising demand.

Although wax tree formation is a ceremony that should be carefully studied and honored in history, we, JewelsPrint present a solution that uses the latest technologies to cover up the problems of old methods. By using grouping, level of precision, and effectiveness, JewelsPrint transforms the jewelry manufacturing process so that businesses can do well even in a competitive market but not forget to regulate the applied artwork within the industry.